The same advantages as our Multi-Ripper but with double the rotation!

Two more teeth spaced equally and agled for maximum ripping force and power!

Available only from Leading Edge Attachments, Inc.

email

sales@leattach.com

for more information

or call us to discuss your special application

508-829-4855

Breaks rock and frost 4 times faster than a hammer, at a fraction of the cost.

Rips the sides and

bottom of the trench flat

with no depth limitation.

How do I benefit?

The Multi-Ripper Multi-plies Your Money!

It lets you do what you couldn't do before!

It increases the effective size of your machine!

How does it do this?

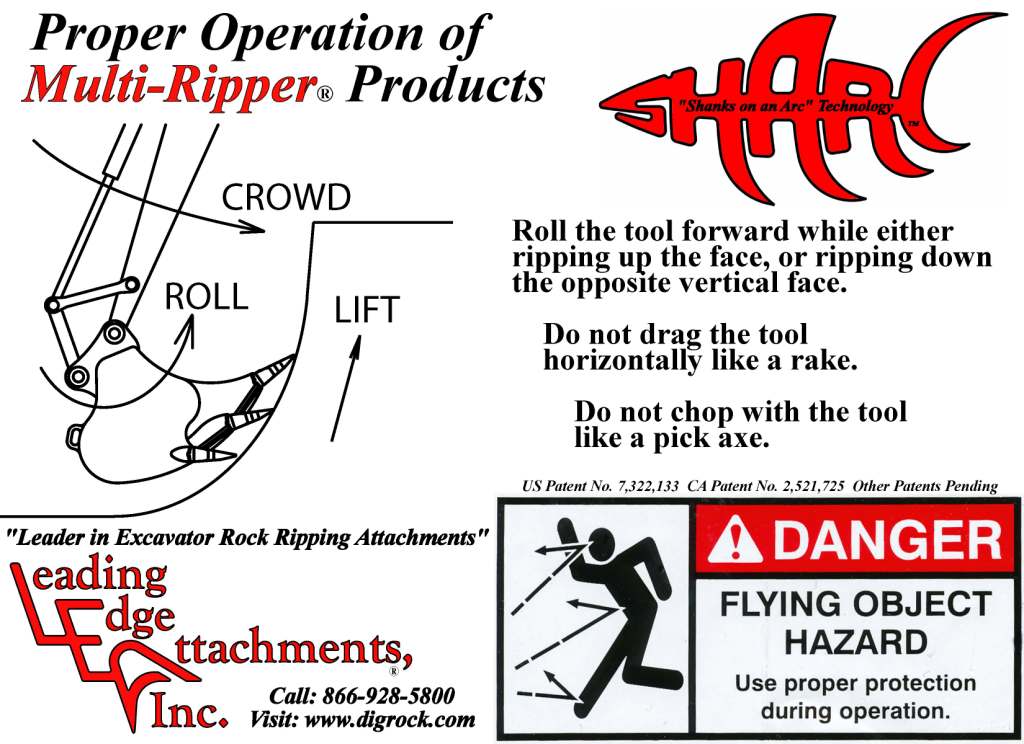

These products rip rock up to

4 times faster than a hammer. They rip 10 times faster than a single

pointed ripper. They greatly exceed all other designs of frost rock,

or ripper buckets on the market. They rip to all depths leaving

relatively flat bottom and side walls in the trench. The staggered shanks on an

arc hit one at a time allowing the maximum breakout to be applied to

each tooth. The tooth force is about 8.5 times that of a standard 5

tooth bucket because the shanks are short. Also, the shanks are the

same distance from the stick pivot, so the shanks rip a relatively

flat bottom.

Why should I believe that it works?

These products have been proven over the past 16 years and have been

granted leters patents in the US and in many countries throughout

the world. These designs won several design awards. Many customers

have claimed this is the best attachment I've ever bought.